SAP Mobilized RF Transactions for Inventory Counts in SAP Inventory Management (IM) and Warehouse Management (WM)

The purpose of these mobilized and automated SAP RF transactions is to perform regularly scheduled, ad hoc (or on-demand), and/or system guided counts of physically on-hand inventory. Examples being Cycle Counts (blind) of full or partial amounts of inventory, full annual Inventory Counts, and the potential requirements for Recounts where discrepancies are identified between what is actually in stock versus what the SAP software identifies as in stock.

What the RF solution should do: using an SAP-certified solution (software and equipment), the Zebra mobile RF barcode scanning device is set up to use as directed, with an inventory list resident on the RF scanner, or to count inventory by location ad hoc. The Zebra RF scanner accomplishes 3 tasks; (1) it tells the user exactly what to scan, (2) it easily collects inventory data and validates and updates the SAP software in real-time, and (3) the system can be designed to display a real-time user message after each scan to verify that the count matches the SAP software or it will direct the user to recount.

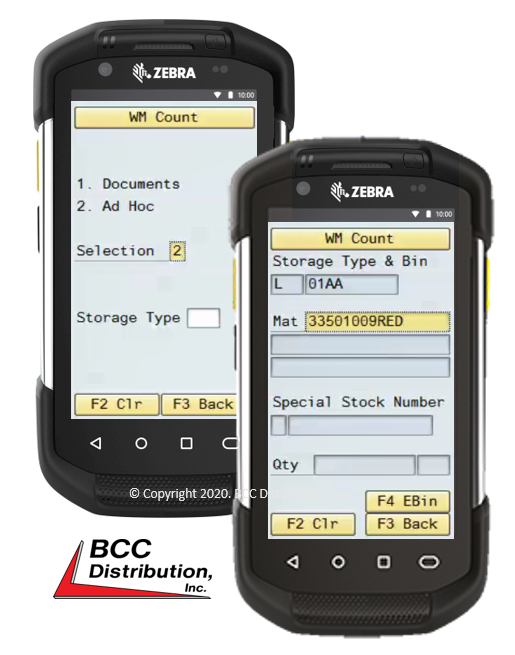

Depending on the business inventory counting processes, the mobilized SAP RF transaction (t-code) for entering a blind Cycle Count may likely utilize MI04 for Inventory Management and LI11N for Warehouse Management. However, a more sophisticated and automated combination transaction may utilize additional SAP t-codes and/or movement types to accomplish various count-related SAP system tasks, such as: for IM- MI01, MI02, MI03, MI05, MI06, and MI07, MI10, MI11, and MI22… and for WM- LI01, LI02, LI03, LI14, LI20, LM59 and LM60. An SAP RF IM Count or SAP RF WM Count, mobilized for use with a Zebra RF scanner, should be easy-to-use and automated for simplicity and real-time SAP system validation:

- From the RF Menu, select the SAP software mobile SAP RF Count transaction (for IM or WM), and then select the Count method to be used- by Document or Ad hoc (on-demand).

- For Warehouse Management (WM), the mobile RF WM Count transaction may be customized for the user to have the option to enter a Storage Type.

- For IM – scan the Storage Location (Sloc) barcode or enter the Sloc number.

- For WM – scan the Bin Location (Bin) barcode or enter the Bin number.

- Scan or enter the Material barcode label to verify you’re Counting the right inventory. The SAP software will provide real-time validation, plus a description of the material inventory.

- The user will then physically count the material inventory in the location, ensuring to verify the UoM (unit of measure). The user will need to confirm that they do not count a box of 10 (for example) as 1 unit. This is a common mistake.

- Once counted, the user will enter the quantity counted via the physical keypad, on-screen keypad, or (if available) by scanning a barcode quantity, with the proper Unit of Measure (UoM). A user confirmation message is displayed if picked correctly.

- Counting transactions may also be customized to provide business specific user feedback for requiring the user to Count again (if did not match), or showing the difference (no longer a blind count).

- The Count will continue until the user has completed the Counts in the Document, or until they are complete with the Ad hoc Count.

- Exceptions or discrepancies are then captures and will require a supervisor to trigger a Recount, or to update the difference(s) in the SAP software.

SAP IM and WM RF Counting Transaction Additional Capabilities:

- For Inventory Management (IM) and Slocs:

- Create Inventory Docs for Cycle Counting

- IM Display, Create, Enter, and Change an Inventory Count Document

- Display Inventory Count with Document and Post Differences

- Dynamic IM Count

- IM Recount Physical Inventory Document

- IM Display Inventory Count Document for Material

- For Warehouse Management (WM) and Bins:

- WM Display, Create, Enter, and Change an Inventory Count Document

- System Guided Cycle Count by Material Document

- User Initiated Dynamic Inventory Count

- User Guided Dynamic Inventory Count

- WM Recount

- WM Clear Inventory Differences

- Utilization of Liner barcodes and 2-dimensional (2D) barcodes- both scanning close and long range (aka extended-range barcode scanning).

Functionality described is for SAP ECC 6.0® and SAP S/4HANA® end users and leveraging SAP Console, SAP ITSmobile, or SAP Fiori / UI5 platform connectivity, combined with 802.11 wireless (WLAN), as well as certified mobile devices such as Zebra or Honeywell RF scanner and wireless device. Images shown may not depict exact mobilized and automated SAP RF transaction or actual Zebra RF barcode scanner, as software and equipment and labeling may vary from end-user to end-user based upon software blueprinting, application requirements, and final recommendations.

Best practice standards are vital to create consistent and easy-to-use RF screens for mobile users, as well as to meet corporate requirements for standardization. BCCD designs each IM and WM transaction for mobile RF scanners (handheld barcode scanners, rugged tablets, vehicle terminals, and more) with minimal words and maximum simplicity, optimized specifically to make the mobile SAP RF scanning and barcode printing system extremely easy to use for the operator. BCCD’s TranASAP solution is developed for real-time, directly-integrated architecture, using the above SAP-certified software development platforms and connectivity tools.

Contact BCC Distribution to illustrate how RF scanning and barcode printing automation can optimize SAP ECC 6.0® and SAP S/4HANA® Inventory Management, Warehouse Management, and Extended Warehouse Management specific to your Inventory Movement process for manufacturing, warehousing, and/or distribution operations.